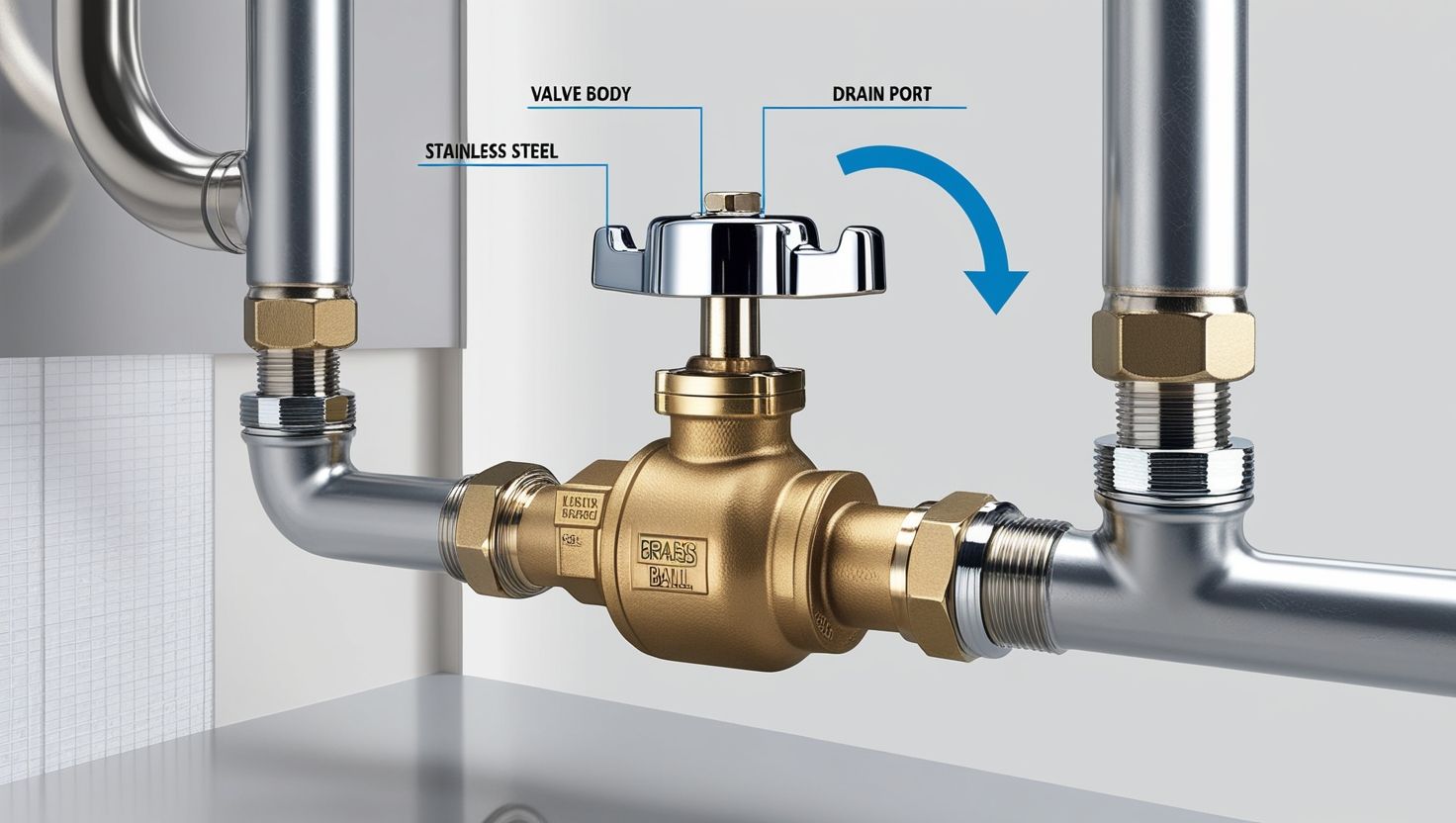

Industries have to install various types of valves as per their conditions. Ball valves are among the ones that have a significant impact on industries. However, it is not about ordinary valves but the ones that have drains. Yes, this is about ball valves with a drainage port. If you know the ball valve’s operating process, here it is. A ball valve has a hollow ball that holds and allows liquid. A handle is attached to it, which helps the operator rotate the ball 90 degrees to either open or shut it. The sealing features are great, and the ball holds the pressure inside the valve pretty well.

What makes this type different from others is its drain port. A tiny section is available in them, which can help operators release the liquid through it. This drain port can have a massive impact on the user experience and industrial applications. Primarily, it is used to drain the excessive content inside the valve. You need this drain port since you can not open the entire valve system to release pressure or excess content. A drain port can help you adjust the pressure inside the valve.

Reducing this quantity is the hardest when there is excessive liquid in the pipeline. However, installing ball valves with a drain system will make things convenient. You can open the drain system to let the excessive liquid drain out. In this way, you can eliminate excessive liquid, whether water or any chemical. This safe removal is possible only through this feature in a ball valve. When selecting the ball valves, try to go for this type. It will make the drainage process possible without making things messy.

Another risk is that two different types of chemicals react with each other. This drainage feature will help if you have to shut down the flow and release the chemical out of the system. Operators can remove the wrong type of chemical from the pipes through ball valves with drainage ports.

Pressure is the most valuable factor in pipelines. Variations in it can cause problems for the overall system. If you have high-pressure flow, which can cause severe damage to valve seals, depressurizing the valve will be a good move. You can do that by releasing the pressure through the drainage ports in this specific type. A ball valve with a drainage port can save lots of effort and liquid waste. You can use this tiny drainage section to release some pressure.

This way, you will adjust the pressure inside the pipelines to maintain the correct flow rate. Factory operators have to work on maintaining the pressure level of valves. They know that too much pressure can damage the seals and seats of the valve. Reducing the pressure will also impact the overall system’s performance. If you install a ball valve with a drainage port, it will save many minor and major components in the valve and pipe systems, allowing them to survive longer.

Valve maintenance is not simple. It requires many steps to clear debris struck inside the valves. However, the maintenance process can be easier if operators use this drainage port wisely. They can remove the debris and corrosion better if they use high-pressure cleaning with the help of a drain system. They will have to make fewer efforts to clean the valves through this drainage port.

The cleaning liquid will clean and exit the valve faster. What they need to do is use the right type of chemicals to wash and release the dirt from the drainage section. This will help the operators get rid of dirt and corrosion properly.

This factor will also affect the overall cost of maintenance. Industries consider these factors in their objectives because each factor matters. If you also consider this factor, installing ball valves with drains will make things cost-effective.

There are some conditions where the pipelines and valves get jammed. These conditions occur in freezing environments usually. The liquid inside the valves and pipes gets jammed in cryogenic conditions. One of the simplest ways to clear that jammed liquid inside the valves is through a drainage port. Ball valves that have drainage ports help operators clear that frozen content easily. Whether it is water or any other nature of the liquid, it can flow out when heated. The exit it needs to flow is a drainage port in a ball valve. This is why a drainage port is important with ball valves.

Ball valves with drains are as useful as any other type of valve. It is all about the right application and the right condition. In conditions where ordinary valves cannot be relied on, these ball valves with drains can sort out challenges.