Introduction:

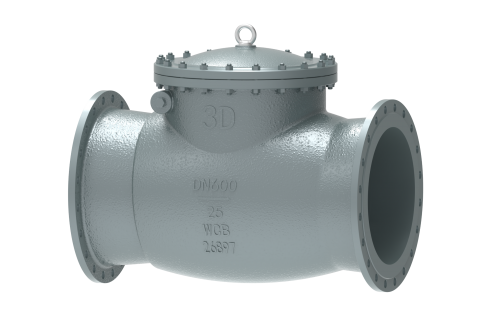

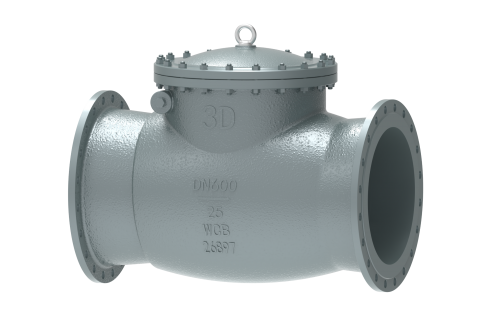

DIN standard cast steel swing check valves are critical components in piping systems, designed to prevent reverse flow of fluids and ensure the safety and efficiency of various industrial processes. These valves adhere to the DIN GOST standards and are widely used in industries such as oil and gas, petrochemicals, power generation, and water treatment.

Features:

1. Cast Steel Construction: DIN standard cast steel swing check valves are manufactured using high-quality cast steel materials, providing excellent strength, durability, and resistance to corrosion.

2. Swing Disc Design: These valves feature a swing disc that pivots on a hinge or trunnion, allowing the disc to freely swing open and closed in response to fluid flow.

3. Renewable Seat Rings: Some valves are equipped with renewable seat rings made from materials such as stainless steel or stellite, ensuring tight sealing and extended service life.

4. Bolted Bonnet: The bolted bonnet design allows for easy access to internal components for maintenance and repair.

5. Flanged Ends: DIN standard cast steel swing check valves typically come with flanged ends for easy installation and connection to piping systems using bolted flange connections.

6. Non-slam Operation: The swing disc design minimizes the risk of water hammer and ensures smooth operation without slamming during opening and closing.

7. Fire Safe Design: Certain valves are designed to meet fire safety standards, incorporating fire-safe seals and materials that withstand high temperatures.

8. Pressure Rating: These valves are available in various pressure ratings to suit different application requirements.

Working Environment:

DIN standard cast steel swing check valves are suitable for a wide range of working environments, including:

1. Oil and Gas Industry: These valves are used in upstream, midstream, and downstream oil and gas operations for flow control and preventing reverse flow in pipelines, refineries, and storage tanks.

2. Petrochemicals: DIN standard swing check valves play a crucial role in petrochemical plants for controlling the flow of various chemicals, gases, and fluids in processing and transportation systems.

3. Power Generation: These valves find applications in power plants for preventing reverse flow in steam, water, and cooling water systems, ensuring the safety and efficiency of power generation processes.

4. Water Treatment: DIN standard swing check valves are utilized in water treatment facilities for preventing backflow in water distribution networks, wastewater treatment plants, and pumping stations.

Working Principle:

1. Normal Operation: During normal operation, fluid flow pushes the swing disc open, allowing fluid to pass through the valve in the forward direction.

2. Reverse Flow Prevention: When fluid flow reverses, the swing disc swings back to its closed position, driven by gravity and the pressure differential across the valve. This prevents reverse flow and ensures fluid flows in the desired direction.

3. Non-slam Operation: The swing disc design allows for smooth opening and closing of the valve, minimizing water hammer effects and ensuring quiet operation without slamming.