Introduction:

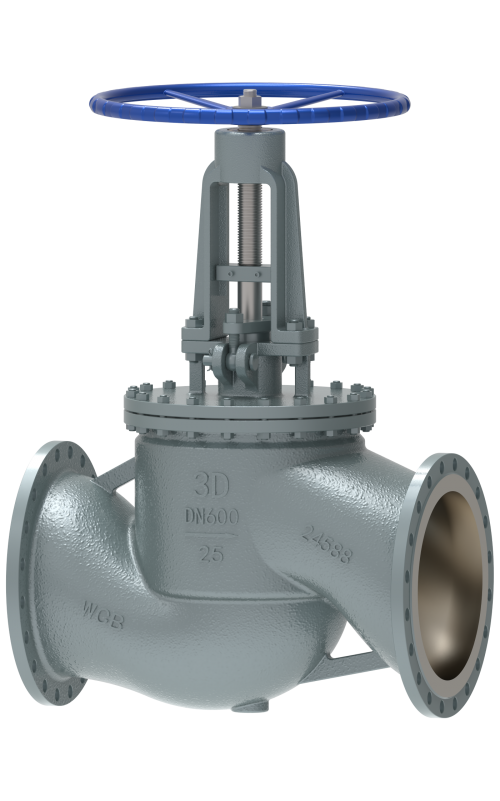

DIN standard manual globe valves are crucial components in fluid control systems, designed to regulate the flow of fluids in various industrial applications. These valves adhere to DIN national standards and are available in different materials and configurations to suit diverse operating conditions.

Features:

1. Robust Construction: DIN standard manual globe valves are constructed with robust materials such as carbon steel, stainless steel, or cast iron, ensuring durability and reliability in demanding environments.

2. Bolted Bonnet: These valves feature a bolted bonnet design, allowing for easy access to internal components for maintenance and repair.

3. Rising Stem Design: Globe valves typically employ a rising stem design, where the stem moves up and down as the valve is operated, providing visual indication of the valve's position.

4. Non-Rising Stem Option: Some valves offer a non-rising stem option, suitable for applications with limited space or where underground installation is required.

5. Flanged Ends: DIN standard globe valves come with flanged ends for easy installation and connection to piping systems using bolted flange connections.

6. Handwheel Operation: These valves are manually operated via a handwheel mechanism, providing precise control over the valve's opening and closing actions.

7. Pressure Rating: Globe valves are available in various pressure ratings to accommodate different application requirements and operating conditions.

8. Versatility: DIN standard globe valves are versatile and find applications in industries such as oil and gas, petrochemicals, chemical processing, water treatment, and HVAC systems.

Working Environment:

DIN standard manual globe valves are suitable for diverse working environments, including:

1. Oil and Gas Industry: These valves are used in upstream, midstream, and downstream operations for flow control in pipelines, refineries, and processing plants.

2. Petrochemical Industry: Globe valves find application in petrochemical plants for regulating the flow of fluids such as crude oil, natural gas, and petrochemical products.

3. Chemical Processing: These valves are employed in chemical processing plants for controlling the flow of corrosive chemicals, acids, and aggressive fluids.

4. Water and Wastewater Treatment: Globe valves play a crucial role in water treatment plants, wastewater treatment facilities, and desalination plants for controlling the flow of water, chemicals, and wastewater.

5. HVAC Systems: These valves are used in heating, ventilation, and air conditioning (HVAC) systems for regulating the flow of chilled water, hot water, and steam.

Working Principle:

1. Normal Operation: During normal operation, the handwheel is turned to raise or lower the valve plug, allowing or blocking the flow of fluid through the valve. The rising stem design provides visual confirmation of the valve's status, indicating whether it is open or closed.

2. Shut-off Operation: To stop flow, the valve plug is lowered onto the valve seat, blocking fluid flow through the valve. The tight sealing provided by the plug and seat ensures leak-free closure.

3. Pressure Resistance: Globe valves are designed to withstand high-pressure conditions without compromising sealing performance or structural integrity.

4. Maintenance: DIN standard manual globe valves require minimal maintenance due to their robust construction. Periodic inspections and lubrication of moving parts may be necessary to ensure optimal performance and longevity.