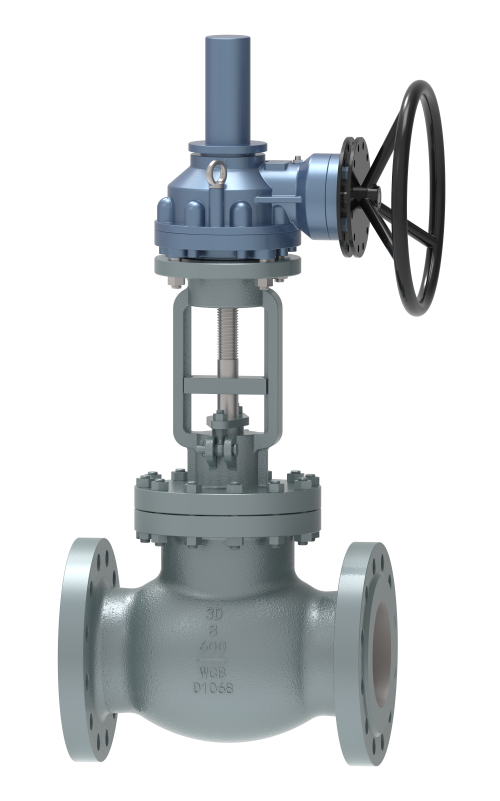

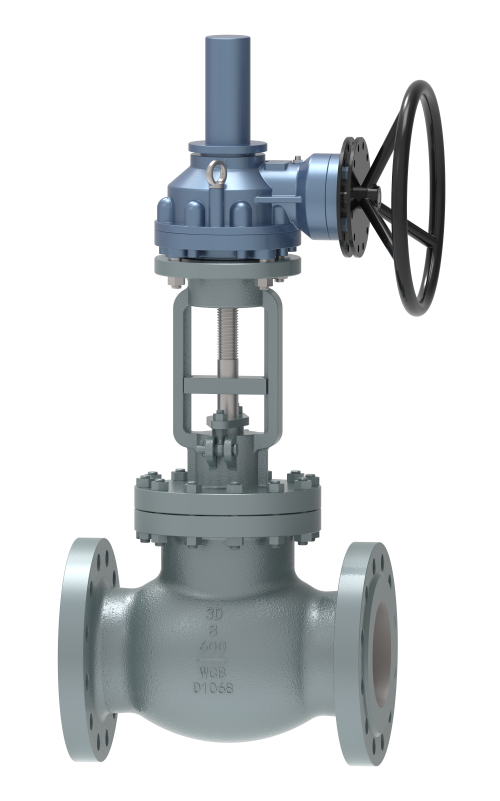

Gear Operated globe valve designed and manufactured to provide maximum service life and dependability. All globe valves are fell ported and meet the design requirements of American petroleum institute standard API600,BS EN13709 and generally conform to American society of mechanical engineers standard ASME B16.34, valves are available in a complete range of body/bonnet materials and trims.

The stems of gear operated globe valves are forged one piece and ACME threaded, then mechanized and finally provided with a smooth finishing in order to minimizing the friction.

Body and bonnets are high quality cast and afterwards precisely machined, directing the attention to prevent stress concentration.

Bonnets are made either of one piece only-the yoke then being an integral part of it-or have two pieces, depending on the size of the globe valve. This ensures the perfect alignment with the body what leads to an accurate opening and closing.

Bodies of globe valves are designed considering the same characteristics as gate valves, which in this case means that disc is guided in bigger valve sizes or high pressure service in order to avoid vibrations and better seat.

Design Features

Design standard as per: BS1873、GB/T 12235

Generally, lift is just 1/4 of the valve seat port, ensuring a short Opening/closing time.

Only one sealing face exists on the valve body and disc.

The valve is designed as a back seat sealing structure.

Use flexible and woven graphite collaboration type packing.

Product Range

Body material: stainless steel, carbon steel, forged steel, alloy steel

Nominal diameter: 1/2"~24"

Pressure range:Class150~2500

End connection: RF, RTJ, BW

Working temperature:-29℃~560℃

Operation: Handwheel, Gear Box, Electric Actuator, etc.

Gear operated Globe valve: refers to the valve whose closure (disc) moves along the center line of the seat. According to the movement of the disc, the change of the seat opening is proportional to the disc travel. Because the stem opening or closing stroke of this kind of valve is relatively short, and has a very reliable cut-off function, and because the change of the seat opening is proportional to the disc travel, it is very suitable for flow regulation. Therefore, this type of valve is very flexible for cutting or regulating and throttling.

Advantage:

(1) During the opening and closing process, the friction between the disc and the sealing surface of the valve body is smaller than that of the gate valve, so it is wearable.

(2) The opening height is generally only 1/4 of the seat passage, so it is much smaller than the gate valve.

(3) There is usually only one sealing surface on the valve body and disc, so the manufacturing process is better and easy to maintain.

(4) Because its filler is generally a mixture of asbestos and graphite, it has a higher temperature resistance. Generally steam valves are cut-off valves.

Disadvantages:

(1) The minimum flow resistance of globe valve is also higher than that of most other types of valves because the flow direction of medium through the valve has changed.

(2) Because of the long travel, the opening speed is slower than the ball valve.

Hot Tags: gear operated globe valve, manufacturers, factory, discount, quotation, pricelist