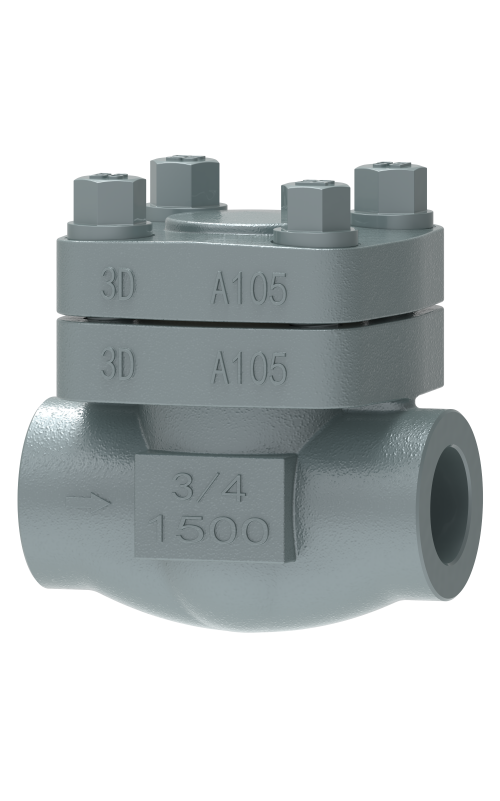

The Forged Steel Swing Check Valve, also known as a Non-Return Valve, is a robust component in fluid control systems, specifically designed for reliable backflow prevention. Crafted through precision forging techniques, this valve is constructed from high-quality steel, ensuring durability and resilience in demanding operational conditions.

The swing check valve operates on a simple yet effective principle. It utilizes a disc or piston that lifts away from the valve seat when fluid flows in the desired direction, allowing unrestricted passage. In the event of reverse flow, the disc is forced back onto the seat, creating a tight seal and preventing backflow.

Forged steel construction enhances the valve's strength and resistance to wear and corrosion, making it well-suited for applications in industries such as oil and gas, petrochemical, and power generation. This durability ensures the valve's reliable performance even in harsh operating environments.

Equipped with a user-friendly handwheel or lever, the valve allows for easy manual operation, facilitating convenient control of fluid flow. It can also be integrated into automated systems for enhanced efficiency in fluid regulation.

Design Features

Design standard as per: API6D, ASME B16.34, GB/T 12236.

Compact and reasonable product structure, reliable tightness and good performance;

Smooth fluid passageway and small fluid resistance;

Swing type disc.

Can be designed with a Damping Cylinder

Rapid closing and flexible actions of the valve disc

Small closing impact, water hammer is not liable to be generated.

Smooth fluid passageway and small fluid resistance.

Product Range

Body material: carbon steel, stainless steel, alloy steel

Nominal diameter: 1/4"~2"(DN15~DN1500)

Pressure range:Class150~2500(PN10~PN420)

End connection: RF, RTJ, BW

Working temperature:-196℃~+560℃