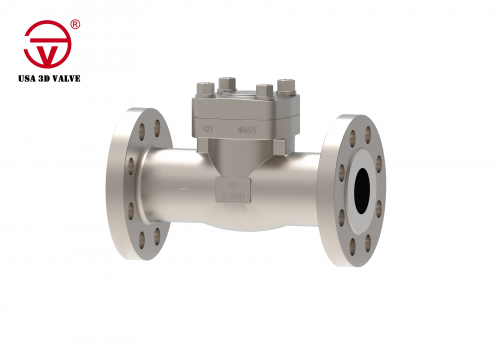

Product Introduction:

The N06625 forged steel swing check valve is a top-level valve that ensures smooth operation and reliability of fluid control systems. This valve is made of high-quality forged steel, which is durable and has long-term performance. Its advanced design provides excellent corrosion and erosion resistance, making it very suitable for use in harsh environments.

This valve has a compact and lightweight design, making it easy to install. The valve stem is sturdy and durable, with extraordinary durability and stability. Its efficient design provides low pressure drop, suitable for a wide range of applications from petroleum and chemical processing to power plants and industrial manufacturing.

N06625 forged steel check valves come in various sizes and configurations to meet specific application requirements.

Merit

1. Durability: Forged steel is used in the manufacturing of N04400 swing check valves to make them sturdy, durable, and wear-resistant. It is sturdy enough to withstand high pressure and extreme temperatures, making it an ideal choice for industries involving harsh conditions.

2. Corrosion resistance: The N04400 forged steel swing check valve has high corrosion resistance and is suitable for conveying different types of fluids, including corrosive fluids. This feature makes it the preferred choice for industries that use harsh chemicals and liquids.

3. Low maintenance cost: The N04400 forged steel swing check valve requires minimal maintenance due to its durability and corrosion resistance, reducing operating costs and saving time and energy.

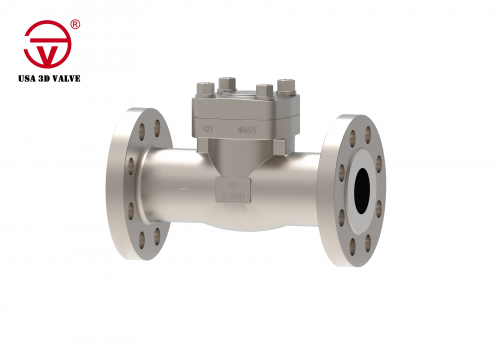

Specification:

Size: 1/2''-2''(DN15~DN50)

Pressure Rating: 150LB-2500LB/PN16~PN160/10K~60K)

Type:Swing Type or Lift

Connections:SW, NPT, RF, RTJ or BW

Suitable Temperature: -29ºC~425ºC.

Application: Water, Steam, Oil and natural gas etc.

Operation: Hand wheel, Gear,Pneumatic actuator & Electric Actuator.

Design Standard:

Design and manufacture:API602,BS5352,ANSI B16.34

Socket welded dimension:ANSI B16.11,JB/T1751

Screw ends dimension:ANSI B1.20.1,JB/T7306

Butt-welded:ANSI B16.25,JB/T12224

Flange ends:ANSI B16.5,JB79

Test and inspection:API598,GB/T13927,JB/T9092