Introduction:

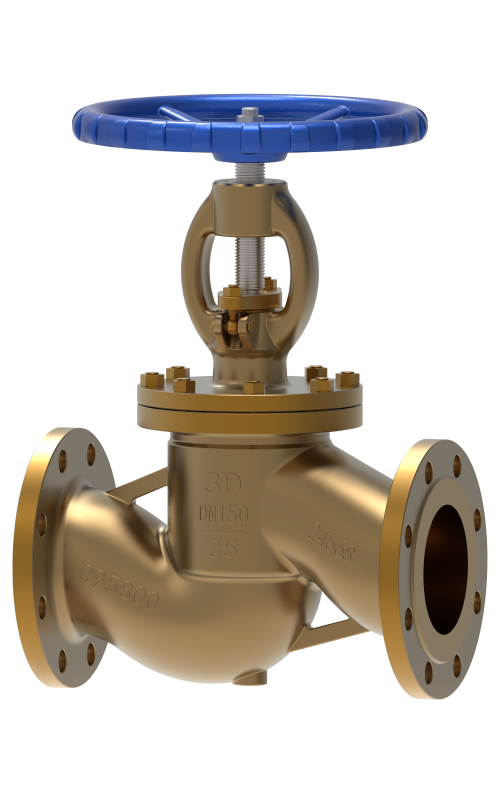

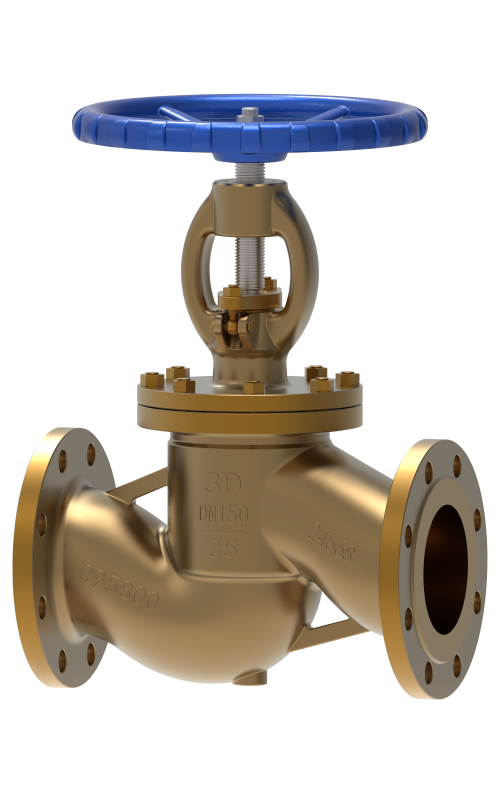

Nickel-aluminum bronze manual globe valves are indispensable components in industries requiring reliable fluid control in corrosive environments. Renowned for their exceptional corrosion resistance and durability, these valves play a crucial role in various applications. This article provides a detailed overview of nickel-aluminum bronze manual globe valves, highlighting their composition, features, applications, and benefits.

Composition:

Nickel-aluminum bronze manual globe valves are primarily composed of copper, nickel, aluminum, and other alloying elements. The addition of nickel and aluminum enhances the valve's resistance to corrosion, erosion, and cavitation, making it suitable for demanding applications in corrosive media.

Features:

1. Corrosion Resistance: Nickel-aluminum bronze valves exhibit superior resistance to corrosion from seawater, acids, alkalis, and other aggressive chemicals, ensuring long-term reliability in harsh environments.

2. High Strength: With a combination of copper and alloying elements, these valves offer excellent mechanical strength, enabling them to withstand high pressures and temperatures.

3. Anti-Fouling Properties: The smooth surface and resistance to biofouling make nickel-aluminum bronze valves ideal for marine applications and environments prone to fouling.

4. Low Friction: Reduced friction and wear characteristics contribute to prolonged service life and smooth operation, minimizing maintenance requirements.

5. Tight Sealing: Precision machining and sealing components ensure tight shut-off, preventing leakage and maintaining process integrity.

6. Versatile Design: Available in various sizes, pressure ratings, and end connections, nickel-aluminum bronze manual globe valves offer flexibility to meet diverse application requirements.

7. Easy Operation: Equipped with ergonomic handwheels or levers, these valves enable effortless manual operation for precise flow control.

Applications:

1. Marine and Offshore Industry: Nickel-aluminum bronze manual globe valves are extensively used in shipbuilding, offshore platforms, and seawater desalination plants for seawater intake, ballast systems, and marine fuel handling.

2. Chemical Processing: These valves find applications in chemical plants for handling corrosive fluids, acids, and alkalis in processes such as chemical synthesis, refining, and storage.

3. Oil and Gas Industry: In oil refineries and gas processing facilities, nickel-aluminum bronze valves are employed for controlling flow in pipelines, refining processes, and offshore drilling platforms.

4. Water Treatment: Municipal water treatment plants utilize these valves for controlling the flow of corrosive chemicals, wastewater, and brine solutions.

5. Power Generation: In power plants, nickel-aluminum bronze valves play a vital role in steam, cooling water, and chemical feed systems, offering reliable performance in corrosive environments.

6. Pulp and Paper Industry: These valves are used in pulp and paper mills for handling corrosive pulping liquors and bleaching chemicals.

Benefits:

1. Longevity: The corrosion-resistant properties of nickel-aluminum bronze ensure extended service life, reducing the frequency of replacements and maintenance.

2. Reliability: High strength and tight sealing mechanisms contribute to reliable performance, minimizing downtime and operational disruptions.

3. Cost Effectiveness: Lower maintenance costs and prolonged service intervals result in overall cost savings over the valve's lifecycle.

4. Environmental Compatibility: Resistance to biofouling and corrosion makes nickel-aluminum bronze valves environmentally friendly and suitable for sustainable applications.

5. Compliance: Meeting industry standards and regulations ensures compliance with quality, safety, and environmental requirements, enhancing trust and credibility.

Conclusion:

Nickel-aluminum bronze manual globe valves are critical components in industries requiring reliable fluid control in corrosive environments. With their superior corrosion resistance, high strength, and versatile design, these valves offer unparalleled performance and longevity in demanding applications. Choosing nickel-aluminum bronze valves ensures operational efficiency, safety, and environmental sustainability in various industrial sectors.