Introduction:

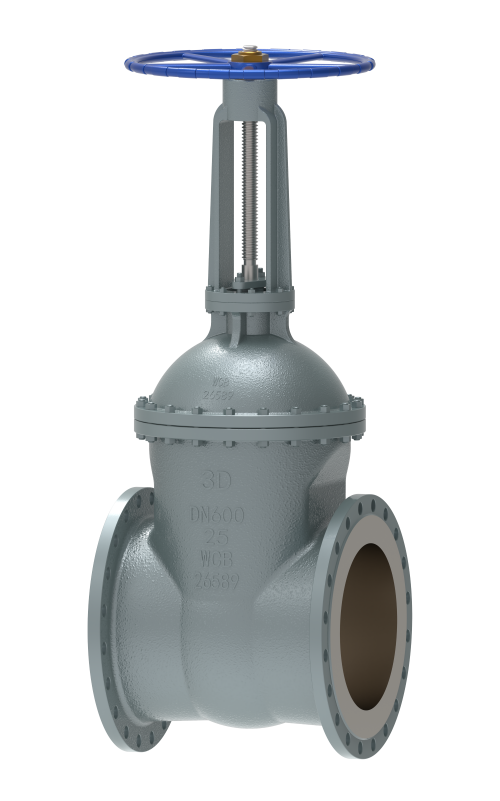

Carbon steel ANSI manual gate valves are essential components in fluid control systems across numerous industries. Known for their robust construction, reliable performance, and versatility, these valves play a pivotal role in regulating fluid flow in various applications. This article provides a detailed overview of carbon steel ANSI manual gate valves, highlighting their features, construction, applications, and benefits.

Features:

1. Robust Construction: Carbon steel ANSI manual gate valves are constructed from high-quality carbon steel, ensuring durability and resistance to wear, corrosion, and erosion.

2. Bolted Bonnet Design: The bolted bonnet design provides secure sealing and facilitates easy maintenance and repair of internal components.

3. Non-Rising Stem: Equipped with a non-rising stem, these valves are suitable for installations with limited vertical space, offering compact and efficient operation.

4. Renewable Seat Rings: Replaceable seat rings ensure a tight seal and extend valve service life, minimizing leakage and maintenance requirements.

5. Full Port Design: The full port design allows for unobstructed flow, reducing pressure drop and enabling efficient fluid handling.

6. API Compliance: Manufactured according to American Petroleum Institute (API) standards, carbon steel ANSI manual gate valves meet rigorous quality and performance requirements for reliable operation.

7. NACE Compliance: NACE MR0175/ISO 15156 compliance ensures compatibility with sour gas environments, making these valves suitable for oil and gas applications.

Applications:

1. Oil and Gas Industry: Carbon steel ANSI manual gate valves are widely used in upstream, midstream, and downstream operations, including wellheads, pipelines, refineries, and petrochemical plants.

2. Chemical Processing: These valves find applications in chemical plants for handling corrosive fluids, acids, solvents, and other aggressive media in processing and storage facilities.

3. Power Generation: Power plants utilize carbon steel gate valves for steam, cooling water, and feedwater systems, providing reliable shut-off and control in high-pressure and high-temperature environments.

4. Water and Wastewater Treatment: Municipal and industrial water treatment facilities employ these valves for controlling the flow of water, sludge, and chemicals in treatment processes.

5. HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems utilize carbon steel gate valves for regulating water and steam flow in heating and cooling systems.

6. Mining and Minerals Processing: Carbon steel gate valves are used in mining operations for controlling the flow of slurry, water, and chemicals in mineral processing and dewatering applications.

Benefits:

1. Durability: High-quality carbon steel construction ensures long-term durability and resistance to wear, corrosion, and erosion in demanding environments.

2. Reliability: Tight sealing, robust construction, and compliance with industry standards contribute to reliable performance and minimal downtime.

3. Versatility: Suitable for a wide range of applications and operating conditions, carbon steel ANSI manual gate valves offer versatility and adaptability to diverse industrial settings.

4. Cost Efficiency: Lower maintenance requirements, extended service life, and reliable performance result in cost savings over the valve's lifecycle.

5. Safety: Secure shut-off capabilities and compliance with industry standards ensure operational safety and environmental protection in hazardous environments.