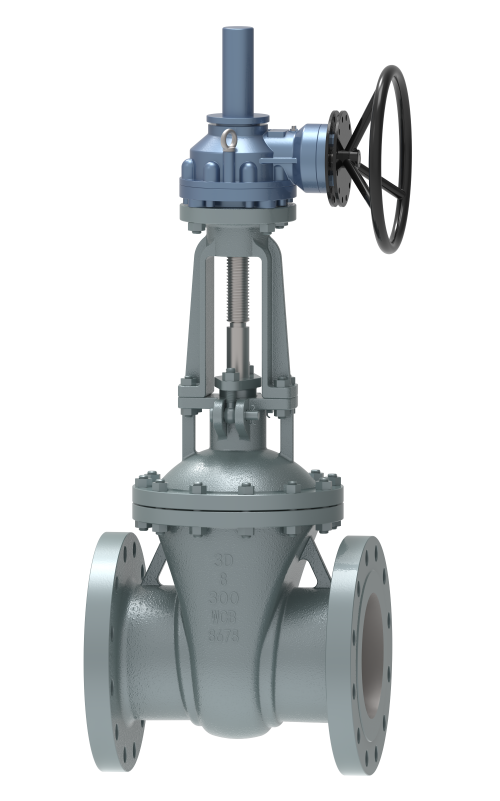

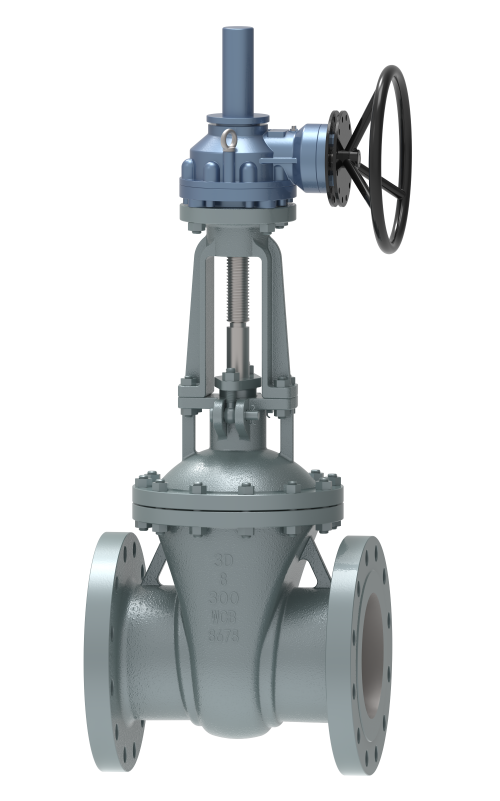

Gear operated Gate valves serve as efficient on-off valves with flow in either direction. In such a design, a wedge slides cross a general passageway in order to control fluid flow (like a sliding gate-hence, the name). One of the most significant characteristics of this type of gear operated valves is its straight-through, unobstructed passageway when set in the full open” position. This is made possible by the wedge lifting entirely out of the passageway. As a result, industrial gate valves are characterized by a minimum of turbulence and pressure drop in operation.

While gear operated gate valves are good for applications requiring these two factors, they are not recommended for installations in which throttling would be a function. They are designed for on/off service.

Gear operated gate valves feature a flexible wedge unless otherwise specified by the customer. The flexible wedge shifts along the body of the valve during opening and closing, being held in position by a guide slot that minimizes the friction between body seat and wedge. This design is especially suited to compensate slight thermal deformations produced by the pipe of the valve itself safeguarding a better sealing between body and wedge seats.

Flexible wedge gate valve

It is a special form of single wedge. Compared with wedge gate valve, it has good sealing performance at high temperature, and the wedge is not easy to get stuck after being heated. It is suitable for steam, high temperature oil and oil, gas and other media, and for frequent switching parts. It is not suitable for medium which is easy to coke.

Design Features

Design standard: API 600.

Small flow resistance for fluid

Only a small force is required for opening/closing.

No limitation on the flowing direction of the medium

During opening and closing process, the friction between the disc wedge and the seat is small, so the sealing is reliable ensuring tightness and long service life.

The valve is designed in a back-seat structure.

The valve stem sealing is realized by the collaboration of flexible and woven graphite. ensuring a more reliable tightness.

Optional pressure seal bonnet type.

Optional solid-wedge type

Optional non-rising stem structures

Optional jacket structure

Product Range

Body material: carbon steel, stainless steel, alloy steel

Nominal diameter:1/2~60

Pressure range: Class150~2500

End connection: RF, RTJ, BW

Working temperature:-29℃~+560℃

Mode of operation: Hand wheel, Gear Box, Electric Actuator, Pneumatic Actuator, etc.