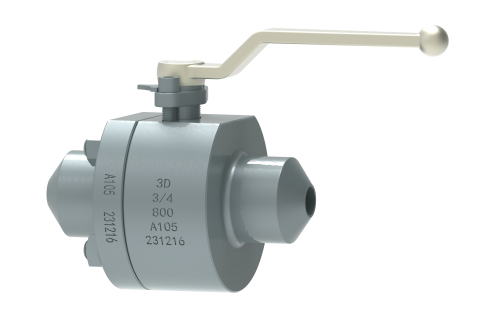

The forged steel ball valve is a robust and reliable component in fluid control systems. Crafted from high-quality steel through precision forging, this ball valve ensures durability and resilience in demanding environments. Its compact design, featuring a spherical closure mechanism, allows for efficient shut-off and regulation of fluid flow.

The valve's compact size and sturdiness make it ideal for applications where space is limited, while its forged construction ensures resistance to corrosion and wear. The precision-engineered steel ball inside the valve provides smooth operation, minimizing friction and wear over time.

Equipped with a lever or actuator for easy manual or automated operation, the forged steel ball valve offers versatility in various industrial settings. Its secure sealing mechanism prevents leaks, enhancing the overall reliability of fluid control systems.

Whether used in oil and gas, chemical processing, or other industries requiring precise fluid regulation, the forged steel ball valve stands out as a dependable and efficient solution, combining strength, durability, and precision in a compact design.

MAIN FEATURES:

2-piece design for fast, economical in-line maintenance

Reinforced TFE seats increase durability

Strengthened construction secures 1500LB rating

Bottom-loaded blow-out proof stem

Mounting pad complies with ISO 5211 for actuation ease and interchangeability

Re,Rp&G Threaded ends comply with BS 21/2779,JIS B-0203/0202,DIN 259/2999,ISO 228-1,AS 1722.1/1722.2 are upon request

NPT threaded ends complied with ANSI B 1.20.1

Basic design complied with ANSI B 16.34&EN 12516-1

Tested according to API 598

Product Range

Body material: carbon steel, stainless steel, alloy steel

Nominal diameter:1/4”;~3”;(DN6~DN80)

End Connection: Threaded Ends (With ISO 5211 mounting pad), Socket Weld Ends (ANSI B 16.11) & Butt Weld Ends (ANSI B 16.25)

Pressure range: Class150 – 300(PN16~PN40)

Operation: lever, electric actuator, etc