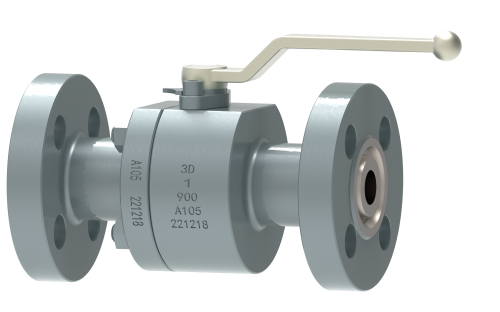

Principle of the forged steel floating ball valve:

This kind of forging ball valve has a floating ball supported by two valve seats. Under the medium pressure effect, a certain displacement can be generated by the ball itself so as to be pressed onto the seat seal ring at the outlet, guaranteeing tightness at the outlet.

No.

Part

Material

1

Bonnet

ASTM A105+ENP A182-F6, F304, F316, F316L, F304L, F51

2

Seat

PTFE RPTFE PEEK PPL

3

Body Gasket

PTFE Graphite

4

Thrust-Washer

A105+ENP A182-F6, F304, F316, F316L, F304L, 17-4PH, F51

5

Stem

Stainless Steel

6

Stop Nut

Carbon Steel

7

Spring Gasket

A216-WCB 10256+Cr

8

Lever

ASTM A182-F304, F316

9

Backup Ring

1015+Cr Carbon Steel+Cr

10

Limited Plate

Stainless Steel

11

Positioning pin

PTFE Graphite

12

Packing

PTFE

13

"O"-Ring

NBR Viton

14

Antistatic Spring

Stainless Steel SS316

15

Ball

ASTM A105+ENP ASTM A182-F6, F304, F316, F316L, F51

16

Body

ASTM A105+ENP A182-F6, F304, F316, F316L, F304L, F51

17

Stud

ASTM A193-B7, B8M, B8, B8M

18

Nut

ASTM A194-2H, 2HM, 8, 8M

Design Features:

The forged steel floating ball valve are designed in accordance with ISO17292、API 608、BS 5351、GB/T 12237;

Simple structure with good tightness and small torque;

Have reduce bore type and full bore type with the minimum flow resistance (zero actually);

Low emission packing;

Fire safe, anti-static and anti-blowout stem design;

Optional locking device

Optional ISO 5211 top flange

Product Range:

Body material: carbon steel, stainless steel, alloy steel

Nominal diameter:1/2"~6"(DN15~DN150)

End Connection: RF, RTJ, BW, THR, SW

Pressure range: Class150 – 2500(PN16~PN420)

Operation : wrench, worm gear, electric, etc