Introduction:

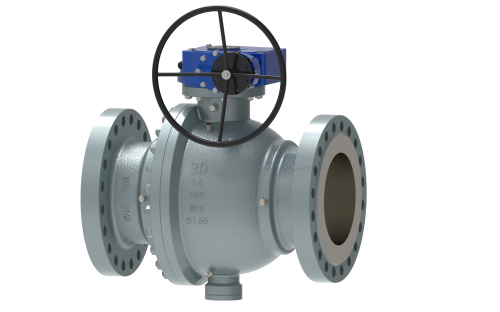

Cast steel abrasion-resistant Trunnion ball valves are essential components in industries requiring reliable flow control and durability in abrasive and erosive environments. These valves are specifically designed to withstand the harsh conditions found in applications such as mining, pulp and paper, and abrasive slurry transportation.

Features:

1. Abrasion-Resistant Materials: Cast steel abrasion-resistant Trunnion ball valves are manufactured using materials such as hardened stainless steel, chromium-molybdenum alloy, or ceramic coatings to withstand abrasive and erosive wear.

2. Sturdy Construction: These valves feature a robust cast steel construction, providing exceptional strength and durability to withstand high-pressure and abrasive fluid environments.

3. Trunnion Ball Design: The ball is securely Trunnion in place within the valve body, preventing movement and ensuring reliable sealing even under high flow velocities and abrasive conditions.

4. Hardened Seats and Seals: Seats and seals are made from abrasion-resistant materials or hardened coatings to withstand wear and maintain tight sealing performance over the valve's lifespan.

5. Blowout-Proof Stem: The valve stem is designed to prevent blowout under high pressure, ensuring the integrity of the sealing system and preventing fluid leakage.

6. Low Torque Operation: Despite their robust construction, cast steel abrasion-resistant Trunnion ball valves are designed for low torque operation, enabling smooth and effortless valve operation.

7. Fire Safe Design: Some valves are designed to meet fire safety standards, incorporating fire-safe seals and materials that withstand high temperatures.

8. Flanged or Threaded Connections: These valves are available with flanged or threaded end connections for easy installation and connection to piping systems.

Working Principle:

1. Shut-off Operation: When the valve is closed, the Trunnion ball rotates to a position perpendicular to the flow direction, creating a tight seal against the valve seats. This prevents fluid flow through the valve, effectively shutting off the flow.

2. Flow Control: By rotating the valve handle or actuator, the Trunnion ball can be positioned to modulate flow rates through the valve. Partial opening of the valve allows for controlled fluid flow while maintaining pressure integrity.

3. Pressure Resistance: The cast steel construction and abrasion-resistant materials used in these valves enable them to withstand high-pressure environments and abrasive fluid conditions without compromising sealing performance or structural integrity.

4. Maintenance: Cast steel abrasion-resistant Trunnion ball valves require minimal maintenance due to their durable construction and abrasion-resistant materials. Periodic inspections and lubrication of moving parts may be necessary to ensure optimal performance and longevity.

Applications:

1. Mining Industry: These valves are used in mining operations for controlling the flow of abrasive slurries, tailings, and process fluids in various stages of the mining process, including ore extraction, transportation, and processing.

2. Pulp and Paper Industry: Cast steel abrasion-resistant Trunnion ball valves are employed in pulp and paper mills for regulating the flow of abrasive pulp slurries, chemicals, and process fluids in paper production and processing.

3. Chemical Processing: These valves find applications in chemical processing plants for controlling the flow of abrasive chemicals, acids, and corrosive fluids in various manufacturing processes.

4. Abrasive Slurry Transportation: Cast steel abrasion-resistant Trunnion ball valves are utilized in pipelines and transportation systems for handling abrasive slurries, wastewater, and industrial fluids in harsh environments.