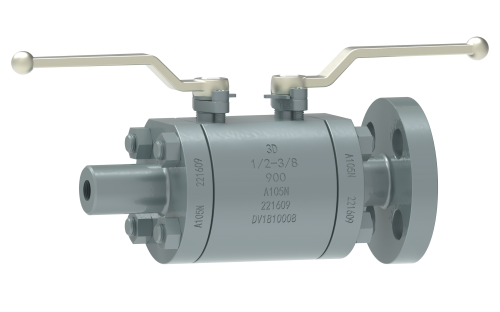

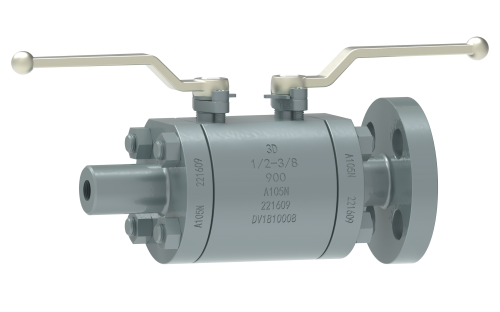

The Double Block and Bleed (DBB) Ball Valve is an advanced fluid control solution designed to enhance safety and efficiency in industrial processes. This valve configuration integrates two seating surfaces within a single valve body, providing a double barrier against the fluid flow. Additionally, it incorporates a bleed port, allowing for the release of trapped pressure between the two sealing surfaces.

The primary function of the DBB Ball Valve is to isolate and secure sections of a pipeline by providing two separate sealing points. This design minimizes the risk of leakage and ensures a reliable shut-off, making it an ideal choice for critical applications in oil and gas, petrochemical, and other high-pressure systems.

The bleed port serves a crucial role in maintaining system integrity. It enables operators to safely bleed off any residual pressure between the two sealing surfaces before maintenance or servicing. This feature enhances safety protocols, reducing the risk of accidents during valve maintenance activities.

Whether used in offshore platforms, refineries, or chemical processing plants, the DBB Ball Valve excels in scenarios where safety and operational reliability are paramount. Its durable construction, often made from high-quality materials such as stainless steel, ensures longevity and resistance to corrosive environments.

In summary, the Double Block and Bleed Ball Valve is a sophisticated fluid control solution that combines dual-sealing capabilities with a bleed port for enhanced safety and operational efficiency in critical industrial applications.

Product Range:

Body material: carbon steel, stainless steel, alloy steel

Nominal diameter:1/2”;~4”;(DN6~DN80)

End Connection: Threaded Ends (With ISO 5211 mounting pad), Socket Weld Ends (ANSI B 16.11) & Butt Weld Ends (ANSI B 16.25),Flanged Ends(ANSI B16.5)

Pressure range: Class150 – 600