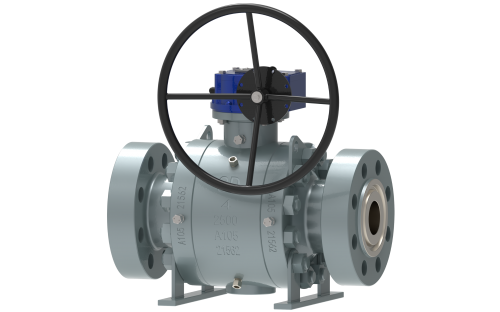

High-precision forged trunnion ball valves are key components in industries requiring precise flow control and reliable sealing, such as oil and gas, chemical processing, and water treatment. These valves are engineered with precision manufacturing techniques to ensure exceptional performance and durability in demanding environments.

1. Forged Construction: High-precision trunnion ball valves are forged from high-quality materials such as stainless steel, carbon steel, or alloy steel, providing superior strength, corrosion resistance, and durability.

2. Precision Machining: These valves undergo precise machining processes to achieve tight tolerances and optimal surface finishes, ensuring smooth operation and tight sealing.

3. Integral Ball and Stem: The ball and stem are often designed as integral parts, minimizing potential leak paths and enhancing structural integrity under high-pressure conditions.

4. Advanced Sealing Technology: High-precision trunnion ball valves utilize advanced sealing technologies such as spring-loaded seats, graphite packing, or PTFE seals to ensure reliable sealing and minimal fugitive emissions.

5. Anti-static Design: Some valves feature an anti-static design to prevent static electricity buildup, reducing the risk of ignition in flammable or explosive environments.

6. Corrosion Resistance: Specialized coatings or materials are employed to enhance corrosion resistance, prolonging the valve's service life in corrosive fluid applications.

7. Low Torque Operation: Precision machining and design optimizations result in low torque requirements for valve operation, reducing the need for large actuators and facilitating manual operation if necessary.

8. Fire Safe Design: High-precision forged trunnion ball valves are often designed to meet fire safety standards, incorporating features such as fire-safe seals and materials that withstand high temperatures.

1. Shut-off Operation: When the valve is closed, the ball rotates to a position perpendicular to the flow direction, creating a tight seal against the valve seats. This prevents fluid flow through the valve, effectively shutting off the flow.

2. Flow Control: By rotating the valve handle or actuator, the ball can be positioned to modulate flow rates through the valve. Precise control of the ball position allows for accurate flow regulation while maintaining pressure integrity.

3. Pressure Resistance: The forged construction and robust design of high-precision trunnion ball valves enable them to withstand high-pressure environments without compromising sealing performance or structural integrity.

4. Maintenance: These valves require minimal maintenance due to their durable construction and advanced sealing technology. Periodic inspections and lubrication of moving parts are typically sufficient to ensure long-term reliability.

1. Oil and Gas Industry: High-precision forged trunnion ball valves are widely used in upstream, midstream, and downstream oil and gas operations, including wellheads, pipelines, and processing facilities.

2. Chemical Processing: These valves are essential for controlling the flow of various chemicals and fluids in chemical processing plants, ensuring precise dosing and mixing processes.

3. Water Treatment: High-precision trunnion ball valves play a critical role in water treatment facilities for regulating the flow of potable water, wastewater, and chemicals used in treatment processes.

4. Industrial Applications: These valves find applications in various industrial processes requiring precise flow control, such as power generation, pulp and paper manufacturing, and pharmaceutical production.

Body material: Carbon steel, stainless steel, alloy steel

Nominal diameter: 2"~24"

End Connection: RF, RTJ, BW

High-Precision Forged Trunnion Ball Valves Class 900~2500LB

Operation: Worm Gear, Electric, Pneumatic, Gas over Oil Actuator and Electro-hydraulic Actuator