Introduction:

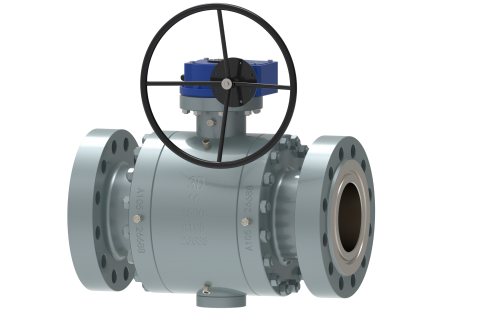

Forged high-pressure trunnion ball valves are critical components in high-pressure fluid handling systems, designed to provide reliable shut-off and control of fluid flow in demanding industrial applications. These valves are forged from high-quality materials to withstand high pressures and harsh operating conditions.

Features:

1. Forged Construction: Forged high-pressure trunnion ball valves are manufactured using a forging process, resulting in a dense and homogeneous structure that ensures strength, durability, and resistance to deformation.

2. trunnion Ball Design: These valves feature a trunnion ball that is securely mounted within the valve body, eliminating the need for dynamic sealing components and ensuring leak-free operation even under high pressure.

3. Metal-to-Metal Sealing: The trunnion ball design provides metal-to-metal sealing between the ball and valve seats, ensuring tight shut-off and preventing leakage in high-pressure applications.

4. High-Pressure Rating: Forged high-pressure trunnion ball valves are designed to withstand extremely high pressures, making them suitable for use in systems operating at pressures ranging from thousands to tens of thousands of psi.

5. Blowout-Proof Stem: The valve stem is designed to prevent blowout under high pressure, ensuring the integrity of the sealing system and preventing fluid leakage.

6. Anti-static Device: Some valves are equipped with anti-static devices to prevent static electricity buildup, reducing the risk of ignition in flammable or explosive environments.

7. Fire Safe Design: Certain valves are designed to meet fire safety standards, incorporating fire-safe seals and materials that withstand high temperatures.

8. Variety of End Connections: These valves are available with various end connections, including flanged, threaded, and welded connections, to accommodate different piping systems and installation requirements.

Working Environment:

Forged high-pressure trunnion ball valves are suitable for a wide range of working environments, including:

1. Oil and Gas Industry: These valves are commonly used in upstream, midstream, and downstream oil and gas operations, including drilling, production, transportation, and refining, where high-pressure fluids are encountered.

2. Petrochemical Industry: Forged high-pressure trunnion ball valves find applications in petrochemical plants for flow control in processes involving the handling of high-pressure gases and liquids.

3. Chemical Processing: These valves are utilized in chemical processing plants for controlling the flow of corrosive and high-pressure chemicals used in various manufacturing processes.

4. Power Generation: High-pressure trunnion ball valves are employed in power generation facilities, including conventional and nuclear power plants, for flow control in high-pressure steam and water systems.

5. High-Pressure Fluid Handling Systems: These valves are used in high-pressure fluid handling systems such as hydraulic systems, hydraulic fracturing (fracking) operations, and high-pressure water jetting applications.

Working Principle:

1. Shut-off Operation: When the valve is closed, the trunnion ball is pressed against the valve seats, creating a tight seal that prevents fluid flow through the valve.

2. Flow Control: By rotating the valve handle or actuator, the trunnion ball can be positioned to modulate flow rates through the valve. Partial opening of the valve allows for controlled fluid flow while maintaining pressure integrity.

3. Pressure Resistance: The forged construction and trunnion ball design of these valves enable them to withstand extremely high pressures without compromising sealing performance or structural integrity.

4. Maintenance: Forged high-pressure trunnion ball valves require minimal maintenance due to their robust construction and reliable sealing mechanism. Periodic inspections and lubrication of moving parts may be necessary to ensure optimal performance and longevity.