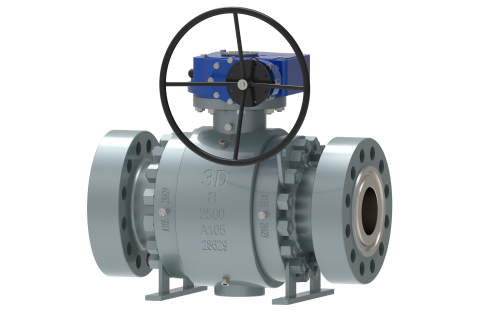

High-performance high-pressure trunnion ball valves are essential components in various industrial applications, particularly in sectors such as oil and gas, petrochemicals, power generation, and refining. These valves are designed to withstand extreme pressure conditions while ensuring reliable operation and minimal maintenance requirements.

Features:

1. Robust Construction: High-pressure trunnion ball valves are constructed using durable materials such as stainless steel, carbon steel, or alloy steel to withstand high-pressure environments and harsh operating conditions.

2. Trunnion Mounted Design: These valves typically feature a trunnion mounted ball design, which provides increased stability and prevents ball movement under high pressure, ensuring tight sealing and enhanced performance.

3. Fire Safe Design: Many high-pressure trunnion ball valves are designed to meet stringent fire safety standards, incorporating features such as fire-safe seals and construction materials that resist high temperatures.

4. Double Block and Bleed (DBB) Functionality: Some valves offer double block and bleed functionality, allowing for isolation and venting of both upstream and downstream fluids for maintenance or safety purposes.

5. Low Friction Operation: Advanced sealing technologies and surface treatments reduce friction between the ball and seats, enabling smooth operation and extending the valve's service life.

6. Anti-blowout Stem: To prevent stem blowout under high pressure, these valves often feature an anti-blowout stem design, ensuring the integrity of the sealing system.

7. High Pressure Rating: High-performance trunnion ball valves are designed to handle pressure ratings ranging from ANSI Class 600 to Class 2500 and even higher, depending on the specific application requirements.

Working Principle:

1. Shut-off Operation: When the valve is closed, the ball is positioned perpendicular to the flow direction, creating a tight seal between the ball and the valve seats. This prevents fluid flow through the valve, effectively shutting off the flow.

2. Flow Control: By rotating the valve handle or actuator, the ball can be positioned to allow precise control of flow rates through the valve. Partial opening of the valve permits controlled fluid flow while maintaining pressure integrity.

3. Pressure Relief: In high-pressure environments, the trunnion mounted ball design ensures that the ball remains trunnion in place, preventing leakage and maintaining pressure integrity even under extreme conditions.

4. Maintenance: High-performance high-pressure trunnion ball valves require minimal maintenance due to their robust construction and advanced sealing technologies. Periodic inspections and lubrication of moving parts are typically sufficient to ensure long-term reliability.

Applications:

1. Oil and Gas Industry: High-pressure trunnion ball valves are commonly used in upstream, midstream, and downstream operations, including wellheads, pipelines, and refining processes.

2. Petrochemicals: These valves are vital components in chemical processing plants for controlling the flow of various chemicals and fluids at high pressures and temperatures.

3. Power Generation: High-performance ball valves are utilized in power plants for steam, water, and gas flow control in boiler systems, turbines, and auxiliary equipment.

4. Refining: Refineries rely on high-pressure trunnion ball valves to regulate the flow of crude oil, petroleum products, and various fluids throughout the refining process.

Product Range

Body material: carbon steel, stainless steel, alloy steel Nominal diameter:2"~24"

End Connection: RF, RTJ, BW

Pressure range: Class900~2500LB

Operation: Worm Gear, Electric, Pneumatic, Gas over Oil Actuator and Electro-hydraulic Actuator